Horse Manure Management for Farming and Homesteading

Quick Facts on Horse Manure

- An average, a 1,000-pound horse produces 9 tons of manure a year containing valuable fertilizer elements.

- Horse owners have a responsibility to manage the manure that is a by-product of their industry.

- Manure is commonly stockpiled prior to use. Adequate storage area allows for greater flexibility in timing of manure use.

- Record keeping is an essential factor in land application of manure/compost.

- The total fertilizer value of the manure produced by Colorado’s horses is estimated to be $10 million per year.

An average 1,000-pound horse produces 9 tons of horse manure a year (50 pounds per day) containing valuable fertilizer elements. (See Table 1.) Add to that an additional cubic foot of bedding material and you get 730 cubic feet/year from one horse. How the manure is stored and treated has a substantial impact on its value. The labor, storage and utilization costs for manure management can be considerable.

Colorado’s horse industry uses two principal feed management systems, according to a recent survey. The first system permits horses to graze full-time on pastures, and manure management is such that the manure is not collected or treated. Pasture manure usually is spread by harrow cultivation that promotes decomposition.

The second system confines animal feeding, which relies on intensive management, and the horses are kept in stalls or runs. The horses may be housed in box stalls and provided a bedding source for urine absorption. Alternatively, horses are kept in corrals or runs, and some runs are attached to stalls.

Horse manure management can happen in one or more of the following ways:

- compost (manure is removed daily and composted);

- stockpiled (manure is removed daily and stored in piles); and /or,

- daily land application (manure is removed daily and spread on cropland).

Marketing Plan for Horse Manure Management

Horse owners have a responsibility for horse manure management that is a by-product of their industry. Develop a management plan for manure and soiled bedding. Use it on crop lands, arena surfaces, trail surfaces, and landscaping. If you don’t plan to use the manure yourself, develop a marketing plan so others can make use of it.

Contract or donate compost to crop farmers and community landscapers or parks, and neighborhood gardeners. Offer a discount to boarders if they dispose of manure. The people who come to watch others ride are another potential market for manure or compost sales. Before you can market the product, it must be completely and properly composted and free of foreign material such as pop cans, wire, and syringes.

Make an arrangement or contract with a landscaper, nursery or crop farmer. Be prepared to handle your own by-product. One option may be to deliver manure, at your cost, to a site where contractors do the composting. Pre-determine the bedding types they prefer in their compost mix.

Horse Manure Management and Collection

Confinement Housing (Stalls, Drylots, and Runs). Daily maintenance of horses in a confinement setting requires intensive labor. Horses housed in stalls and sheds require soft absorbent bedding. The most common bedding sources in Colorado are pine sawdust (80 percent), pine wood chips (17 percent), and straw (2 percent). Some other sources are shredded newsprint, peanut shells, peat moss, rice hulls, etc. Remove horse manure and soiled bedding on a regular basis and handle appropriately to prevent fly infestation and disease transmission.

Pastures. Horse manure management in pastures depends primarily on getting good distribution of manure across the pasture. To avoid manure concentration in isolated spots in a pasture, distribute grazing evenly. Rotational grazing is one of the best ways to achieve this goal; however, horse owners don’t usually have large enough pastures for rotational grazing.

On the other hand, pastures can be split, and the horses moved back and forth between both parts of the pasture to distribute the manure more uniformly. Availability of several watering facilities and moving feeding facilities periodically will encourage better manure distribution.

Avoid grazing during rainy periods when soils are saturated, to avoid soil compaction and manure runoff. Restrict access to streams to avoid manure deposition in or near water bodies. This can be done by fencing or providing shade away from the streams. Refrain from excessive stocking rates that lead to overgrazing. Damaging the grass stand increases manure runoff potential from pastures.

Horse Manure Management and Stockpiling.

Horse manure is commonly stockpiled

prior to use. Adequate storage area

allows for greater flexibility in timing of manure use. Therefore, be

sure you have a large enough storage area to accommodate the manure

produced. Over time, the manure shrinks from decomposition and moisture

loss.

Proper site

selection for the storage area is important to safeguard against

surface and groundwater contamination. Place stockpiles at least 150

feet away from surface water (creeks and ponds) and wells. Establish

and maintain grass buffer strips between water bodies and manure piles.

Construct a perimeter ditch or berm around the storage area, if needed,

to prevent runoff onto or off of the area.

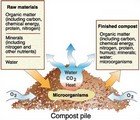

Composting

produces a relatively dry end-product that is easily handled and

reduces the volume of the horse manure (40 percent to 65 percent less

volume

and weight than the raw manure). Composting at proper temperatures can

kill fly eggs and larvae, pathogens and weed seeds. Compost has less of

an odor compared to raw manure and is more easily marketed. Composted

manure acts as a slow release fertilizer and an excellent soil

conditioner.

To be done right,

composting requires an investment of time and money. Machinery required

includes a tractor, a manure spreader and a front-end loader. Some

ammonia-nitrogen is lost during the composting process, and an ammonia

odor may result for a short period. When composting is done on a large

scale, additional land and machinery requirements exist.

Microbes that drive

the composting process require optimum conditions of temperature,

moisture, oxygen, and carbon:nitrogen (C:N) ratio. The C:N ratio should

be between 25:1 and 30:1; horse manure has an estimated C:N ratio of

50:1. With the addition of bedding material (high carbon content), the

C:N ratio will be even higher. Therefore, N has to be added to the

manure for it to compost properly.

The addition of grass clippings,

hay, or fertilizer [25 to 30 pounds N/ton of manure (75 to 90 pounds of

ammonium nitrate or 50 to 65 pounds of urea)] should bring the C:N

ratio into the optimum range. When microbes work properly, the compost

temperature will be between 120 and 160 F. Cooler temperatures result

from a lack of N. When the composting process is complete, the

temperature will cool naturally.

It is important to

have the right balance of moisture and air for the microbes to process

the horse manure. The compost should be moist but not soggy, and may

need to

be watered or covered with plastic to maintain moisture. Aerate the

compost by turning it regularly. The manure and bedding particles

should be about one-half inch to one and a half inches in size.

Composting does require effort, but the result is a more easily used

and economically valuable fertilizer.

Horse Manure Management and Application of Manure

Horse Manure Management for Land Application

Record keeping is an essential factor in land application of manure/compost. It is critical to know how much manure/compost was applied to each field and when it was applied. Analyze manure/compost regularly and record the lab results for future reference. Note changes in nutrient value and factor them in when calculating future application rates.

Manual loading and land application are labor intensive and impractical for managing the manure generated by more than 25 horses. Consider mechanical loading and application with a bobcat or tractor-operated loader when the manure or the land application becomes large.

Apply the horse manure/compost uniformly to achieve an acceptable application rate. The finer textured and more uniform the manure, the easier it is to apply uniformly. Spreaders apply manure/compost at different rates depending on ground speed, PTO speed, gear box settings, discharge openings, and manure moisture and consistency.

Do not apply horse manure to land that is highly erodible, frozen or saturated. To protect water sources from manure runoff, do not spread manure within at least 150 feet of a water source (such as a well, creek or pond). Incorporate manure into the soil as soon as possible. Mixing the manure with the soil immediately reduces losses of manure nutrients to runoff and volatilization, and reduces odor problems associated with manure left on the soil surface.

Base the manure/compost application rate on crop N needs and available soil and manure N levels. Test your soil and manure for N levels at a certified laboratory. In general, the higher a crop yield goal, the greater the N requirements. Irrigated crops also tend to need more N. If yield goals are lower than those shown in Table 2, decrease the manure application rate and increase the land application area. If yields are higher, less land is needed. Soils high in organic matter and nitrate have higher available N in the soil and require less N.

| Table 1: Average fertilizer content in horse manure (as-is basis). |

|

N/ton

|

19 lb

|

|

P2O5/ton

|

14 lb

|

|

K2O/ton

|

36 lb

|

|

Table 2:

Average manure application rates and land base (area) requirements for

forages.

|

|||

|

Forage

|

Yield

|

Annual Horse

Manure Application

|

Land Base

Needed

|

|

(tons/acre)

|

(tons/acre)

|

*(acres/horses/yr)

|

|

| Alfalfa |

2.0

|

15

|

0.6

|

| Alfalfa-grass |

2.0

|

10

|

0.8

|

| Bentgrass |

1.0

|

10

|

0.8

|

| Big bluestem |

1.5

|

5

|

1.8

|

| Birdsfoot trefoil |

1.5

|

12

|

0.8

|

| Bluegrass |

1.0

|

10

|

1.0

|

| Bromegrass |

1.5

|

10

|

1.0

|

| Little bluestem |

1.5

|

6

|

1.6

|

| Orchardgrass |

2.0

|

10

|

1.0

|

| Red clover |

1.5

|

10

|

0.8

|

| Reed canarygrass |

2.0

|

9

|

1.0

|

| Ryegrass |

2.0

|

11

|

0.8

|

| Switchgrass |

1.5

|

6

|

1.6

|

| Tall fescue |

2.0

|

13

|

0.6

|

| Timothy |

1.5

|

6

|

1.6

|

| Wheatgrass |

0.5

|

2

|

3.8

|

| *The land base needed is the cropland requirement for manure application alone, not for grazing and forage needs. One ton = 2,000 lbs. One acre = 43,560 sq ft. | |||

Horse Manure Mangement for Landfills

Manure and compost are sometimes landfilled, dumped in gullies and used to repair roads. These are not recommended practices due to high runoff and leaching potential from gullies and roadways. If the areas are not vegetated and are waterways for storm runoff, the potential for runoff of manure nutrients into creeks and ponds is high. When excessive nutrients exist in surface waters, plant and algal growth becomes extreme, the oxygen supply is depleted, and fish can be killed.

Horse Manure Management for Riding Arenas

An ideal arena surface provides resilient footing for optimum horse performance. Drain the arena well, maintain adequate depth to protect horses’ legs from contusions, and keep the arena absorbent to hold moisture efficiently and prevent dust. The arena surface also must be odor-free. Composted manure/bedding makes an ideal surface addition when mixed with river sand and wood products. Uncomposted manure and bedding results in ammonia fumes that can cause respiratory problems in horses. Surface depth of compost depends on soil type and climate; too much organic matter can hold excess moisture and may cause the horses to slip and fall.

| Table 3: Maximum manure application rates to avoid soil salinity problems. | |||

| Manure EC* | Soil EC* | ||

|

1

|

2

|

3

|

|

|

10

|

84 T/A

|

56 T/A

|

28 T/A

|

|

20

|

30 T/A

|

20 T/A

|

10 T/A

|

|

30

|

18 T/A

|

12 T/A

|

6 T/A

|

|

40

|

12 T/A

|

8 T/A

|

4 T/A

|

| *mmhos/cm; T = Ton; A = acre | |||

|

EC = electrical conductivity measured in units of millimhos/centimeter. Note: The manure application rate should be based on N needs of the crop within this maximum range. This table assumes that manure is not incorporated, which is typical for perennial forage crops. |

|||

Horse Manure Management and Precautions

Virtually no viral diseases are transmitted between horses and humans through fecal material, but some bacteria and protozoans (such as E. coli and Giardia) can be transmitted in this manner. Therefore, handle horse manure carefully to prevent disease transmission. In addition, horse manure runoff into waterways may produce fecal coliform contamination levels that can be potentially hazardous to fish and anyone who drinks that water.

Horse Manure Management and Runoff

Runoff water from dry lots, pastures, and manure storage or compost areas carries pollutants (such as nitrogen, phosphorus, and bacteria) into surface waters. Avoid over-irrigation of pastures. Build berms or trenches to prevent water from entering or leaving dry lots and manure storage and composting areas. Do not allow a creek or irrigation canal to pass through drylots.

Parasite Prevention and Control

Horses pick up parasites by ingesting grass, feed, or water that is contaminated with parasite larvae and eggs. The most common internal parasites of horses are the ascarids, strongyles (large and small), pinworms and bots.

Horse Manure and Insect Control

Excellent fly-breeding conditions occur in mixtures of manure, spilled feed and decaying bedding. To help eliminate these areas, remove and spread the manure regularly and prevent accumulation of other wastes. Composting at proper temperatures inhibits fly development. Several pesticides can be used on manure piles to kill maggots. However, we would suggest planting the following in and around the paddocks to deter flies:

- lavender

- mint

- southernwood

- wormwood

- basil

Cover manure stockpiles or compost sites to exclude flies and prevent their development.

Non-composted horse manure piles can provide an ideal environment for the bumble flower beetle white grub. White grubs feed on decaying manure; however, these grubs do not damage home lawns. Therefore, there is no need to control them.

Mosquitoes require standing water to reproduce; therefore, it is imperative to prevent ponding of water in manure storage areas.

Horse Manure and Salinity

Manure tends to be high in salts, which when land applied at excessive rates, contribute to soil salinity. Soil salinity causes plants to become water stressed or, in extreme cases, die. When manure is not soil-incorporated, as in applications to pasture, the salts accumulate on the soil surface unless they are leached into the subsoil. Irrigation or rainfall may move salts out of the topsoil and move them into deeper depths of the soil profile. If salinity levels in the soil and manure are known, use Table 3 to determine acceptable maximum rates of manure application for most forages to avoid excessive soil salinity (>4 mmhos/cm).

Horse Manure Management and Weeds

A weed is an unwanted, out-of-place plant. Weeds compete with crops for limited resources of water, nutrients and light. Manure has contributed to weed problems where it has been applied to cropland. Use composted horse manure to avoid these problems. When manure is composted, the high temperatures achieved during the composting process kill most weed seeds. Some weed infestations may be the result of overgrazing, not due to manure applications.

Parasite Preventions and Controls in Horse Manure

De-worm all horses on a regular schedule.

Horse Manure Management for Parasite Control:

A.

Remove all

manure from stalls, small corrals, and paddocks on a daily basis.

B.

Compost all manure to a temperature of 145 F for at least two weeks to

kill most parasite eggs, or compost at lower temperatures for longer

periods of time.

C.

Spread manure on pastures only after composting.

D.

Manure that has not been composted should be spread only on crop land

or other ungrazed, vegetated areas.

Horse Manure and Pasture Management:

A. Mow two to four times a year and chain harrow (drag) to break up manure pile and expose parasite eggs to the elements.

B.

Don’t overstock.

C.

Practice rotational grazing if possible.

D.

Graze young horses separately from

older horses; the younger horses

have a higher susceptibility to parasites.

E.

Follow horses with cattle or sheep

before returning a pasture to

horses. This interrupts the life cycles of horse parasites.

F. Deep harrow or plow pastures that are badly parasite-infested. Deep plow pastures and reseed every three to five years. This also helps break parasite cycles.

Feed and Water Management:

A.

Use feeders, racks, bunks or mangers for feeding hay and grain. This

will prevent feed from getting mixed with feces. Don’t feed off the

ground.

B.

Provide horses a clean, fresh drinking water supply.

C. Avoid water contaminated with feces.

by J.G. Davis and A.M. Swinker

Resources

Spencer, W., and D. Tepfer. 1993. 3.762, Economics of composting feedlot manure. Colorado State University Cooperative Extension.

Wilson, C.R., and J.R. Feucht. 1991. 7.212, Composting yard waste. Colorado State University Cooperative Extension.

Waskom and Davis. 1999. BMPs for Manure Management, Colorado State University bulletin no. 568a.

Source: Colorado State University Equine Extension

New! Comments

Do you have something of value to add? Leave me a comment in the box below.